Slickline Surface Equipment : CAMCO Liquid Seal Head

|

| Slickline Surface Equipment : CAMCO Liquid Seal Head |

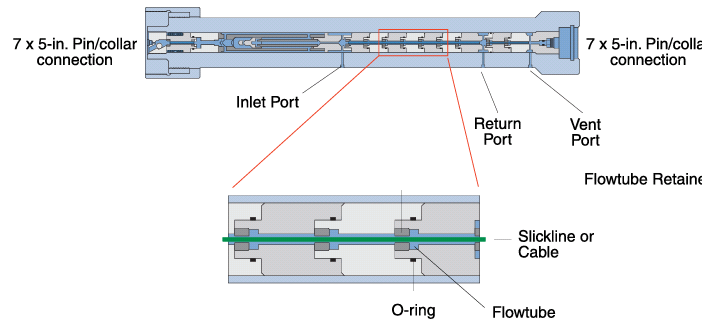

The slickline pressure liquid seal head was developed to replace conventional stuffing boxes that employ mechanical packing assemblies. The liquid seal head contains a combination of wireline seal bores and a gas control mechanism. The design allows for superior control of well pressure with in a shorter assembly length. A liquid seal is created around the wire by a pressurized seal fluid. The pressure - tight, low -friction seal is created between the wire OD and the multi - stage, precision - machined wireline seal bores. A gas separation system located with in the degasser section of the liquid seal head isolates gas bubbles from the lines that only seal fluid fills the void between the OD of the line and the ID of the seal bores. A controlled volume of seal fluid is allowed to exhaust into the well tubing during operations. To inhibit the effects of H2S or other corrosive fluids, the seal fluid is premixed with inhibitor. The liquid seal head coats the wire going into the hole with lubricant and inhibitor. While coming out of the hole, contaminated fluids are removed and the wire is coated with fresh inhibitor before it is spooled on the slickline reel.

[post_ad]

[post_ad]

Slickline Surface Equipment : CAMCO Liquid Seal Head

Reviewed by Unknown

on

12:39 AM

Rating:

Reviewed by Unknown

on

12:39 AM

Rating:

Reviewed by Unknown

on

12:39 AM

Rating:

Reviewed by Unknown

on

12:39 AM

Rating:

No comments:

Thank you for visit and read this post. Share this post if you like it.

Leave your comment on this text box