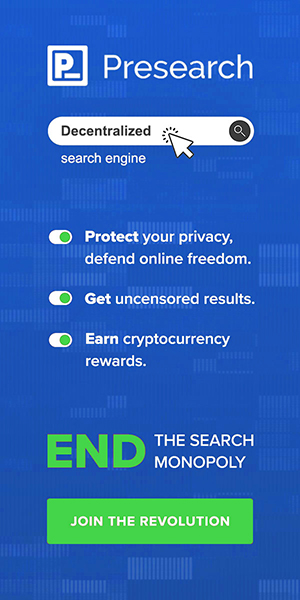

The Logging Environment

|

| Figure 1 - Logging Environment |

Zones A, B, C and D are porous, permeable zones containing fluid; these are separated by impermeable shales. Casing is cemented into the borehole across the entire interval; each zone should be hydraulically isolated. Zones A, B, and D have been perforated to establish communication with the formations. (When a number of zones are perforated in the same wellbore, as shown in the figure, the zones are said to be commingled.) The completion results shown in this figure indicate some problems with this well. Zone A is producing, whereas zone B is not. Zone B is "stealing" fluid production which would otherwise be produced to the surface, and thus is said to be a thief zone. From the inside of the wellbore, it would appear that zone D is producing properly, although examination of the figure indicates that this is not the case. A defect in the cement job has allowed communication between zones C and D, and the result is a "channel" in the cement through which zone C is produced. From the schematic, it is not clear whether zone C is just producing or is also flooding zone D.

These problems—the sources and losses of production, the presence of channels, and the possibility of zone C flooding zone D—are the types of issues addressed by cased-hole logging techniques. Cased-hole operations present special problems not seen in openhole logging, especially especiallly with respect to formation evaluation. Again, it is clear from Figure 1 that the logging tool is not adjacent to the formation, but instead is inside the pipe which, in turn, is separated from the formation by cement or by a channel. The channel may be filled with mud, water, oil, or gas, and cement of unknown thickness may be present. Certain tools are serious1y affected by wellbore fluids. The region below the lowest perforations (the rathole) may be filled with water, while the wellbore immediately above the perforations across zone D is filled with oil. Apparent gas entry from zone D has caused the wellbore fluid above this zone to become gas-cut. There are clearly many variables in the wellbore environment that affect the response of cased-hole logging tools.

[post_ad]

[post_ad]

One way to classify cased-hole logs is by their Primary area of investigation. Moving from the center of the wellbore in Figure 1 , four regions are encountered: the inside of the well-bore, the casing wall, the annulus between the casing and the formation, and the formation itself (labeled by Roman numerals I, II, III, and IV, respectively). A cased-hole logging tool is generally designed to investigate one of these four regions. Flow evaluation devices measure fluid movement inside the well-bore; casing inspection surveys examine the pipe itself; cement-bond logs scan for cement annular fill; and formation evaluation sensors measure the shaliness, porosity, water saturation, and other formation properties. Each sensor, while having a primary region of investigation, may be secondarily or adversely affected by the other regions.

TweetFollow @industrimigasTweet to @industrimigas

The Logging Environment

Reviewed by Industri Migas

on

2:55 AM

Rating:

Reviewed by Industri Migas

on

2:55 AM

Rating:

Reviewed by Industri Migas

on

2:55 AM

Rating:

Reviewed by Industri Migas

on

2:55 AM

Rating:

No comments:

Thank you for visit and read this post. Share this post if you like it.

Leave your comment on this text box