Wellhead Valve Operating Precautions

|

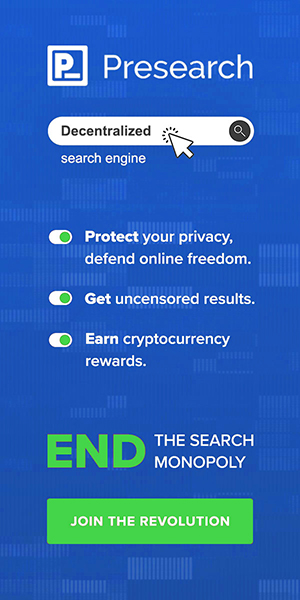

| Wellhead and chrismast tree configuration |

The valves must be operated carefully when opening or closing. Some valve types have a shear pin between the handle and stem, which will shear to protect the valve’s internal components, if excessive force is applied. The master valve should not be used to close in a flowing well, except in an emergency. The swab or wing valves are typically used. Each time the gates of the valve shut in a flowing well, the increase in velocity of the well fluids during the closing action can cause wear across the seal faces. It is easier and safer to replace the seats and gates in valves, other than the master valve in the tree. Always count the number of valve turns made when closing. This is a prudent check against jamming the toolstring or wire in the tree, in the event that the tools have been raised fully into the lubricator.

Tubing Hanger

The tubing hanger is the device that supports the production tubing within the tubing head. A seal assembly on the body of the tubing hanger provides a hydraulic seal between the tubing hanger and the body of the tubing head. Tubing hangers, in most circumstances, are designed with an extended neck which seals in the bottom of the adapter flange to isolate the well fluids from the tubing head ring joint seal.

Internal profiles on the tubing hanger provide a means for inserting a tubing back-pressure valve (BPV). The body of the tubing hanger is ported for the routing of a small control line that is connected to the sub-surface ball valve. The threaded connections top and bottom of the tubing hanger are compatible with the tubing string being suspended. In the lifetime of the wellhead, the tubing hanger is the component that will most commonly be removed and replaced.

[post_ad]

Christmas Tree

The Christmas tree is an assembly of valves and fittings used to control the flow of the well fluids and provide access into the tubing string or production conduit. The adapter flange is the connection on the bottom of the Christmas tree that mates with the top flange of the tubing head and is of the same size and pressure rating of the tubing head flange.

The internal profile of the adapter flange accepts the extended neck of the tubing hanger, with some designs of adapter flange the profile will include a secondary seal. Around the outside of the bottom flange are a series of fittings for test ports and bleeder ports. These ports are used to energize the secondary pack-off and perform a ring joint test between the two mating flanges, the lower annulus seal, and the secondary pack-off. To match up with the porting on the tubing hanger neck, an additional port is used for the control line fluid to pass to the downhole safety valve. The top connection is used for the first valve of the Christmas tree. In a bolt-up style of tree, normally the adapter flange is integral to the Christmas tree valve and termed as part of the Christmas tree unit.

In a composite style Christmas tree, the adapter flange will form the bottom flange of the Christmas tree.

Wellhead Valve Operating Precautions

Reviewed by Industri Migas

on

9:47 PM

Rating:

Reviewed by Industri Migas

on

9:47 PM

Rating:

Reviewed by Industri Migas

on

9:47 PM

Rating:

Reviewed by Industri Migas

on

9:47 PM

Rating:

I'm really inspired together with your writing skills and also with the layout for your weblog. Get more info about triple offset butterfly valve manufacturer in USA

ReplyDeletenice bLog! its interesting. thank you for sharing.... gate valve

ReplyDeleteGreat survey, I'm sure you're getting a great response. vibrating screen

ReplyDeletethank you for your interesting infomation. globe valve

ReplyDeleteI found that site very usefull and this survey is very cirious, I ' ve never seen a blog that demand a survey for this actions, very curious... valve ari armaturen

ReplyDeletenice bLog! its interesting. thank you for sharing.... increase itunes sales

ReplyDeleteI went over this website and I believe you have a lot of wonderful information, saved to my bookmarks adult humor books

ReplyDeleteVery nice article, I enjoyed reading your post, very nice share, I want to twit this to my followers. Thanks!. tetris unblocked

ReplyDeleteYour website is really cool and this is a great inspiring article. Thank you so much. when was photography invented

ReplyDeleteOutstanding as well as powerful suggestion by the writer of this blog site are truly valuable to me. Carbon Steel Pipe suppliers

ReplyDeleteThis is a very good article, do visit Lakshya Steel International

ReplyDeletegood content please visit Prashaant Steel & Alloys

ReplyDeleteloved the content really insightful please check our site

ReplyDeleteDinesh tube link

please visit our site Steel Pipes Tube USA

ReplyDeleteReally helpful article! please do visit our website MLG India

ReplyDeleteloved the article, please visit Gayatri Tube India

ReplyDeleteVery Informative blog that help us understand information easily and fast. Keep sharing more information. If you are looking for the best Stainless steel supplier in India do check out our products below:

ReplyDeletehttps://www.amardeepsteel.com/astm-a312-a213-a249-tp316-stainless-steel-seamless-welded-pipes-tubes.html